tack welding sheet metal vs screws Tack welding is a quick pre-welding process of applying small dot-like beads throughout the joint’s length. The number of required tack welds depends on the joint . Our wide range of parts includes everything from motors and drives to circuit boards and cables. We source our parts from reputable manufacturers to ensure durability and compatibility with a variety of CNC machine models.

0 · when to use tack welding

1 · what is a tack welding

2 · what is a standard tack weld

3 · temporary tack welding

4 · tack welding techniques

5 · spot vs tack welding

6 · pros and cons of tack welding

7 · advantages of tack welding

Reduce risk and get to launch faster with sheet metal fabrication for aerospace components—from rapid prototyping to low-volume production.

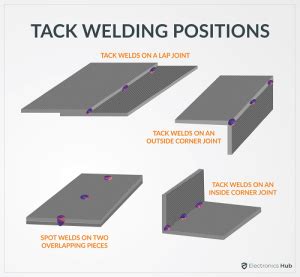

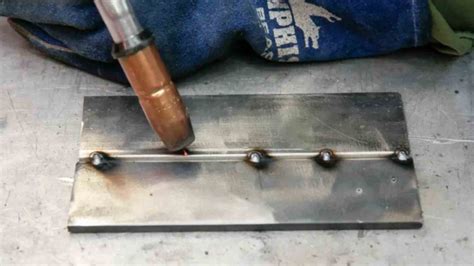

Spot welding creates a permanent weld by compressing two pieces of sheet metal with copper electrodes, while tack welding is a low-heat, . Tack welding is a quick pre-welding process of applying small dot-like beads throughout the joint’s length. The number of required tack welds depends on the joint .Welding is historically one of the most common sheet metal fastening methods. The welding technique is a fabrication process consisting of two or more parts fused through heat or pressure. Conventional fasteners used for this method .Tack welding is a crucial step in metal fabrication. It involves creating small, temporary welds to hold pieces in place before final welding. This method ensures proper alignment, reduces distortion, and allows adjustments before .

Tack welding is often used when welding large pieces of metal together, because it is easier to position the pieces correctly when they are only held together by a tack weld. Tack welding is a common practice in many .(Definition and Guide) Tack welds are small and temporary welds that hold parts together ready for final welding. Using tack welds mean that fixtures may not be required to hold parts together to create a finished weld. Tack welds maintain .

Let’s highlight the five most common types: Standard Tack Weld: The standard tack weld is suitable when providing support for the final weld is a consideration. This type of weld is typically large enough to bear the weight of the welded .

Conclusion. FAQs. What is Tack Welding? A tack weld is a temporary weld used to hold two or more pieces of metal in place before performing a final weld. This method commonly involves the use of low heat and a short welding arc to join .Tack welding is a term used to spot tack metal when fabricating with your welding machine. In this guide we review the best tack welding methods and skills to be an effective tack welder. Common Types of Sheet Metal Welding Process “How to weld sheet metal” is the most common question that follows. There are a variety of techniques and strategies for welding sheet metal, and each has its own set of . - Position panels and secure with sheet metal screws. Place screws where ever necessary to pull panels together tightly. - Tack weld top joint with MIG every 1 ½ - 2 inches. Tack weld the bottom side every 3 inches approx. - Remove screws and weld holes. - Dress welds. - Liberally paint (brush) top and bottom seams with MasterSeries silver.

Spot welding excels in high-speed production lines, providing strong and durable welds for sheet metal components. Tack welding, on the other hand, offers versatility and temporary alignment for various applications, reducing distortion and allowing for adjustments before final welding. Understanding the attributes and applications of each . When you attach the drawer sides to metal drawers, do yall tack them on or drill and secure with screws? What kind? . thread forming screws for blind holes in 10 ga metal and 8-32 pan head machine screws w/ nylon insert hex nuts for attaching the drawers to the slides. . easy to weld.easy to prime and paint. The sheet metal shop sheared .nuts and bolts, rivets, screws, special fasteners), resistance and tack welding methods and techniques, adhesive bonding of components and self secured joints (such as knocked up, paned . SEMPEO222 Producing sheet metal components and assemblies 8. SEMPEO222 - . Generally speaking, you want to match the MIG wire thickness to the metal you are welding together. If you are doing a lot of dedicated sheetmetal work, you should stick to thinner wire such as 0. .

Welding can only be performed on similar materials: Stronger Joints: The lack of a heat source (required for weld nuts) produces no weak points due to thermal effect: The welding process increases the chance for thermal stress or annealing: Reduced Weight: A mechanically attached nut is typically lighter than a weld nut while maintaining .

Learn more about different methods used for sheet metal welding, including advantages in various applications and decide which techniques will best suit your industrial applications. 07 3088 9274. HOME; . Tack welding Tack welding can be used to prevent the risk of warping. These hold the position of the sheet properly. 8. Welding techniques Spot welding vs tack welding: Differences in unique strengths and limitations. . and then the electrodes squeeze the pressure on the molten metal to create a weld. In other words, the spot welding process relates to modifying pressures, electrical inputs, and current durations. . Poor fit-up of the parts or having the sheet edges too close . First screw the sheet metal together along the edge with a lap joint. Space screws apart about 4". After you get a tack every 2" along the seam remove the screws and perform a plug weld to fill the holes. . The 1/16" easy strike and Lincoln 6013 are the only option for stick welding sheet metal. make very short tack welds and space them out . It’s best if your welder supports a tack weld timer. For example, Eastwood MIG 180 lets you create repeatable tack welds with the same amperage input and arc duration. If your welder doesn’t support a tack timer, you may keep the arc lit for too long on some tack welds, which inputs too much heat compared to the other tacks, warping the material.

Tack welds are placed at the ends of the joint and at regular intervals along the vertical piece to hold it in place. Tack welding in a T-joint is important to prevent the vertical piece from shifting during the welding process. 4. Pipe Tack Welding . Tack welding is especially important in pipe welding to ensure proper alignment of the pipes. Guys, watched many videos where a flange tool is used to "crimp" about 5/8", cut new panel to lay on that, sheet metal screws to "tighten" new/old panel together, then start welding that line. Then that 5/8 overlap just is tapped down in trunk once done?Welding is historically one of the most common sheet metal fastening methods. The welding technique is a fabrication process consisting of two or more parts fused through heat or pressure. Conventional fasteners used for this method include tack weld and spot weld fasteners. These types of screws work particularly well for softer materials such as aluminium, plastic, and thin sheet metal. Because they pierce materials rather than drill them, they offer a cleaner, more aesthetically pleasing finish. .

Sheet metal screws are a special type of fastener designed specifically for metal sheets, utilizing the interplay of internal and external threads to secure sheet metal. . Welding titanium is a specialized skill requiring a . Does a tack weld require full penetration? Regardless of the type of metal, if the joint requires full penetration, the tack weld requires full penetration as well. If you need full penetration of your tack (weld) on stainless steel, be .

Both spot and projection weld fasteners have their place. Spot welding fasteners resistance-weld directly to a sheet with either a rocker-arm or a press-type resistance welding system (see Figure 1 and Figure 2).Projection fasteners, which have small protrusions on the surface that fuse to the base metal, require a press-type machine.

Welding or Bolting vs gluing panels on, a science project.. Follow up peel test from my sons science project on Welds vs Glue. . In preparing to do my shadetree floorpan panel "addition", I figured that I could use some drill point sheet metal screws to initially locate everything, then use some of the aerospace-rated panel adhesive our .

If you are tack welding multiple pieces of sheet metal together, it is important to clean the area around each tack weld before making another weld. This will help to prevent defects in the final weld. Tack welding is a simple and commonly used type of welding, but it is important to do it correctly to get good results. .

A strong and versatile alternative to weld nuts and challenging spot weld and tack weld processes. PennEngineering® Portfolio; Haeger® Sherex® PROFIL® HEYCO® View All ; . Weld vs. Self Clinch Comparison Chart Compare Self Clinching to Weld. . Reverse side of metal sheet remains flush; No retapping necessary after application; I am learning TIG welding - getting better. I have a scenario where I need to weld a bolt (as a stud) to a Jeep firewall. The bolt is a flat head allen bolt, like a furniture bolt. I don't want to blow a hole in the firewall or melt the bolt trying to weld it. For practice, I welded a couple of hex bolts to some 1/4" stock and burned up the bolt head.

I have used both. Taking my time I find the clecos work the best since I use a pneumatic flanger/puncher. When I am too lazy to pull out the puncher or on a curved surface, I use the screws. I prefer the "self-drilling sheet metal" vs. the "pierce and twist sheet metal" type. The self-drillers usually make a cleaner hole to weld up later.

barber electrical enclosures

Tack Welding vs Spot Welding: Key Differences Purpose. Tack Welding: Primarily used for temporary alignment and stabilization before final welding. Spot Welding: Used for creating permanent, strong joints, particularly in sheet metal applications. Process. Tack Welding: Involves creating small welds at intervals along the joint.Welding Sheet Metal for Aluminum, Steel, and Stainless Steel, etc. Custom Sheet Metal like Auto Parts Welding Now! . What’s the Difference Between Tapping and Drilling Screws? Nov 03, 2024. Read. What is the Difference Between Thread Tap and Thread Mill? Oct 31, 2024. Read. Zintilon Technology Co., Ltd.I’m a beginner mig welder trying to learn how to join together two pieces of sheet metal like that on a car that I’m planning on welding in the future. I have two questions and a one problem. . The problem I am having is when I tack between the two pieces sometimes I get good penetration and the tack crosses the gap however the weld is . Difference Between Tack Weld vs Fillet Weld. When choosing between tack welding and fillet welding, it’s essential to consider the type of application you’re working on. Tack welding is perfect for those working on large, heavy materials as it holds them together before you can make the final weld. Fillet welding, on the other hand, is best .

when to use tack welding

what is a tack welding

We are a leading manufacturer of custom machined parts for a wide range of industries. Our state-of-the-art machining shop is equipped with 3, 4, and 5-axis CNC milling and turning capabilities, allowing us to handle even the most complex parts with precision and accuracy.

tack welding sheet metal vs screws|advantages of tack welding